Precision measurement for blasting, coatings, corrosion control, and QA/QC compliance.

Why DeFelsko? The Industry Benchmark for Precision Inspection

In Australia’s demanding industrial landscape—spanning mining, marine, oil & gas, transport infrastructure, and protective coatings—accurate surface inspection is the backbone of corrosion control.

DeFelsko instruments are relied upon worldwide for their proven durability, precision, and ease of use. Built for both the laboratory and the toughest field environments, they deliver dependable performance every time:

- Industry-leading measurement accuracy – backed by decades of metrology expertise

- Rugged, weather-resistant designs – many models rated to IP65 or better for dust, moisture, and jobsite exposure

- Simple, intuitive user interfaces – available in both touchscreen and keypad-operated models

- Rapid, repeatable readings – with advanced microprocessors and smart probe technology

- Long-form NIST- or PTB-traceable Calibration Certificates – included at no extra cost

- Full compliance with relevant Australian and international standards – including AS/NZS, ISO, SSPC, and ASTM methods

- The universal PosiTector body platform – allowing multiple probes to connect to a single gauge for coating thickness, environmental, profile, soluble salt, and inspection workflows

DeFelsko gauges enable contractors, inspectors, and asset owners to ensure complete compliance with Australia’s protective coating standards while reducing rework, delays, and premature coating failures.

1. PosiTector® 6000 – Coating Thickness Gauge for Metal Substrates

Conforms with AS 2331.1.4, AS 3894.3-B

The PosiTector 6000 is the flagship coating thickness gauge engineered for steel and non-ferrous metal substrates. Using magnetic induction and eddy current principles, it provides extremely fast and accurate coating thickness readings without calibration adjustment for most applications.

Technical Features

- Dual-technology probe for ferrous and non-ferrous metals

- Ruby-tipped wear-resistant probe ensures long-term accuracy

- Over 60 readings per minute

- Large 2.8” impact-resistant touchscreen

- Advanced statistics: mean, max, min, standard deviation

- USB, WiFi and Bluetooth connectivity

- Fully weatherproof, dustproof IP65 enclosure

Best for:

Industrial painting contractors, marine fabricators, tank builders, structural steel coating QA, and any protective paint application requiring precise DFT (Dry Film Thickness) measurement.

2. PosiTector® 200 – Coating Thickness Gauge for Non-Metal Substrates

Supports AS/NZS 1580 series methods

The PosiTector 200 uses ultrasonic pulse-echo technology to measure coating thickness on wood, concrete, plastic, composites, and GRP—substrates where conventional electromagnetic gauges cannot operate.

Key Capabilities

- Measures total coating thickness or up to 3 individual layers(Advanced models)

- Ideal for polyurea, epoxy flooring, powder coating on MDF, and fibreglass components

- No destructive cutting or cross-sectioning required

- Ready to measure out of the box

Standards Alignment

While Australia does not have a dedicated ultrasonic coating thickness standard, PosiTector 200’s method aligns closely with AS/NZS 1580 coating test principles.

3. PosiTest® PC – Uncured Powder Coating Thickness Gauge

Industry standard for predictive powder coverage

A non-contact ultrasonic gauge designed for uncured powder coatings, allowing applicators to predict final cured film thickness before curing—reducing rework, reducing waste, and improving throughput.

Technical Highlights

- Up to 4× faster measurement speed

- Excellent for conveyor-line and swinging part inspection

- No calibration required for most powders

- Scan Mode for continuous measurement of large surfaces

Ideal Applications

Aluminium extrusions, OEM parts, general powder coating shops, and architectural finishing.

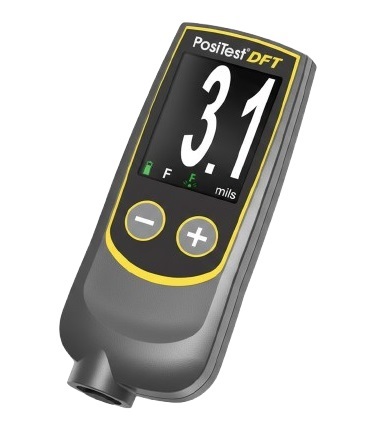

4. PosiTest® DFT – Cost-Effective Coating Thickness Gauge

Conforms with AS 3894.3-B

A compact, economical gauge offering DeFelsko quality in a simplified unit—available in Ferrous only or Ferrous + Non-Ferrous (Combo) models.

Key Features

- 60+ readings per minute

- Zero or 1-point calibration for complex surfaces

- Auto-rotating display

- On-screen averaging for batches of up to 99 readings

Best For

Contractors and QA teams who need reliable DFT measurement without advanced data features.

5. PosiTest® AT – Pull-Off Adhesion Tester

Conforms with AS/NZS 1580.408.5

The PosiTest AT verifies coating bond strength using hydraulic pull-off testing—critical for assessing surface preparation quality and coating adhesion on:

- Steel

- Concrete

- Timber

- Rigid composites

Why Adhesion Testing Matters in Australia

High UV exposure, marine atmospheres, and extreme temperatures all demand strong coating adhesion to prevent early corrosion.

Technical Features

- 10, 14, 20 and 50 mm dollies for varying strength resolutions

- Self-aligning aluminium dolly ensures correct load distribution

- IP65 weather-sealed housing

- ±1% accuracy via NIST-traceable load cell

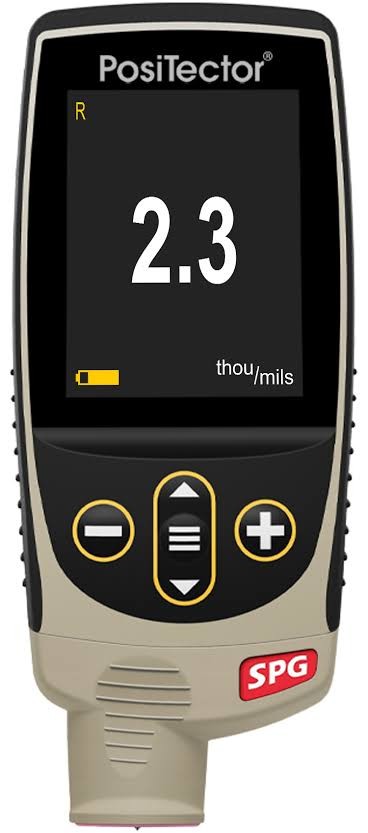

6. PosiTector® SPG – Surface Profile Gauge

Conforms with AS 3894.5-C (with optional 30° tip)

Surface profile depth is essential for anchor pattern performance. PosiTector SPG measures peak-to-valley height after abrasive blasting to ensure compliance with coating manufacturer requirements.

Technical Advantages

- Measures >50 readings per minute

- Field-replaceable tungsten-carbide tip

- Ideal for steel infrastructure, pipelines, marine hulls

- Eliminates subjectivity of replica tape

- Digital record-keeping for QA documentation

7. PosiTector® DPM – Dew Point Meter for Environmental Monitoring

Aligns with ISO 8502-4 (commonly referenced in Australia)

The #1 cause of coating failure is moisture-related contamination. The PosiTector DPM measures:

- Relative humidity (% RH)

- Air temperature

- Surface temperature

- Dew point

- ΔT (difference between surface temperature and dew point)

- Wind speed (optional)

Why It Matters

Coatings should never be applied when ΔT < 3°C — a rule followed widely across Australian industrial sites.

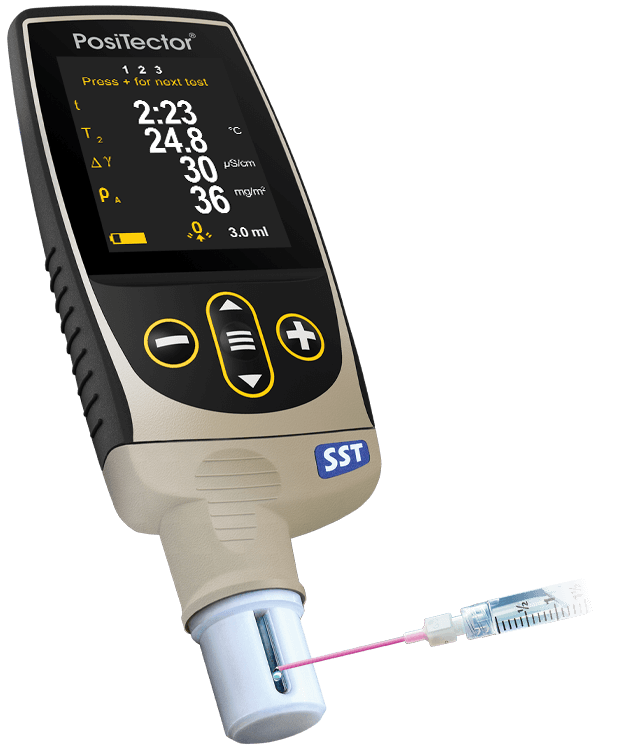

8. PosiTector® SST – Soluble Salt Tester (Bresle Test Method)

Conforms with AS 3894.6

Designed specifically for soluble salt contamination testing, ensuring steel surfaces are free of chloride, sulfate, and nitrate ions prior to painting.

Features

- Displays conductivity, sample temperature, and surface density (mg/m²)

- Automated interface guides users through ISO 8502-6/8502-9 steps

- Built for high-salt environments common in Australia’s coastal and offshore sites

9. PosiTest® LPD – Low Voltage Holiday Detector

Conforms with AS 3894.2

Used to detect pinholes, holidays, and discontinuities in thin-film coatings on steel and concrete.

Benefits

- Four voltage output modes

- GroundSense™ verifies proper grounding

- Ideal for pipeline coatings, tank exteriors, and general steelwork

10. PosiTest® HHD – High Voltage Holiday Detector

Conforms with AS 3894.1

For thick, high-performance coatings and linings. Available in stick-style pulsed DC or compact wand-style continuous DC.

Key Features

- Voltage calculator (input coating thickness → auto-set test voltage)

- Supports rolling springs, wire brushes, and custom electrodes

- ±5% voltage accuracy

DeFelsko + Quantum Blast Delivers Complete Inspection Confidence

DeFelsko gauges give Australian contractors the accuracy, ruggedness, and standards compliance they need to deliver coatings that last—supported locally by Quantum Blast’s technical expertise, supply reliability, and industry knowledge.