Industrial Edition – Quantum Blast Australia

A detailed industrial guide for Victoria’s manufacturing, transport, marine, rail and defence sectors. Includes blasting equipment, abrasive media, coating systems and regional

recommendations.

A detailed industrial guide for Victoria’s manufacturing, transport, marine, rail and defence sectors. Includes blasting equipment, abrasive media, coating systems and regional

recommendations.

Victoria is one of Australia’s most diverse and high-demand industrial regions. With strong activity across manufacturing, transport, rail, defence, marine, heavy engineering and infrastructure, abrasive blasting plays a critical role in extending asset life, removing corrosion, and preparing surfaces for high-performance coatings.

Unlike Queensland’s climate-driven maintenance cycles, Victoria’s blasting work is shaped by:

High workshop productivity expectations

Fast turnaround requirements

Strict coating specifications for rail, transport and fabrication

Consistent demand for precision, efficiency and compliance

Quantum Blast supports this industrial load with a full equipment and media ecosystem, supplied directly from our Victorian distribution base at Metro Freight Lines, 75–79 Cooper St, Campbellfield VIC.

Victoria is dominated by high-output dry blasting workshops, and GritBlast is the system of choice for fast, reliable, and precision-controlled abrasive blasting.

Ideal for:

• Steel fabrication

• Rail maintenance and refurbishment

• Truck, trailer & fleet rebuilders

• Container repair workshops

Key Advantages:

High-efficiency abrasive metering

Robust, workshop-ready construction

Compatible with all major abrasive media

Optimised for single-use almandine garnet

Low maintenance and high uptime

Suitable for small and large industrial facilities

Victorian workshops value productivity, and GritBlast delivers aggressive cutting speed, reliability, and consistent performance across demanding operational environments.

RapidBlast is the all-rounder for operators who require both mobility and workshop-grade performance. It is widely used by:

Mobile blasting contractors

Medium-duty fabrication workshops

Transport fleet refurbishers

Rail component maintenance teams

With adjustable blasting power and easy setup, RapidBlast provides high flexibility for on-site and in-house operations.

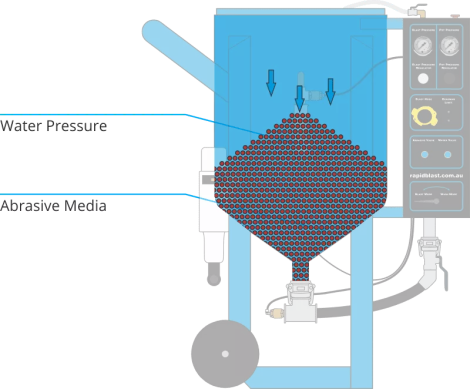

Wet blasting systems such as VAPR-Blast are essential across Victoria’s urban, marine, food and manufacturing sectors. By injecting water into the blast stream, these units significantly reduce dust, allowing safe operation in confined, sensitive, or hygiene-controlled environments.

Ideal For:

• Food processing plants

• Pharmaceutical facilities

• Marine maintenance (Geelong, Hastings)

• Urban cleaning and restoration

• Brick, stone and façade cleaning

VAPR-Blast improves visibility, reduces airborne contaminants, and minimises cleanup — making it a preferred choice for safety-focused industrial operators.

Vapour blasting cabinets deliver premium finishing and surface refinement for industries requiring absolute precision. These systems are popular in Victoria’s advanced manufacturing and restoration markets.

Applications:

Automotive & motorcycle restoration

CNC machining and component finishing

Aerospace and defence manufacturing

Stainless and alloy component refurbishment

These cabinets produce a clean, satin finish without damaging delicate surfaces.

Vacuum blasting systems enable blasting and media recovery simultaneously, maintaining extreme cleanliness and reducing contamination risks.

Widely used in:

• Food and beverage manufacturing

• Pharmaceutical facilities

• Enclosed or hygiene-sensitive workshops

• Rail depots

• Transport fleet workshops

These systems help Victorian operators meet compliance standards while reducing media consumption and waste.

Victoria is a major coatings and corrosion-control market. Quantum Blast supplies industry-leading Graco and Wagner equipment to provide end-to-end workflows from blasting to coating.

Airless sprayers (electric & pneumatic)

Plural component sprayers

Industrial coating systems

Line marking machines

Diaphragm pumps

Aircoat spray systems

Pressure pots and industrial spray guns

Advanced finishing systems

This integrated equipment range ensures Victorian operators can blast, coat and finish with maximum efficiency.

Abrasive media usage in Victoria differs from coastal states due to climate, industrial density and workflow preferences. Almandine garnet remains the most widely used abrasive statewide, supported by steel grit, crushed glass, aluminium oxide and glass bead.

Almandine garnet is the dominant media for Victorian fabrication, rail and manufacturing workshops due to:

High cutting efficiency

Low moisture absorption (important in cooler climates)

Excellent surface profile consistency

Fast cleanup and easy disposal

Economic performance for single-use blasting

When paired with GritBlast systems, garnet provides exceptional speed and finish control.

Crushed Glass – heritage restoration, brick/stone cleaning, marine work

Steel Grit & Shot – rail workshops, blast rooms, heavy engineering (high recycling value)

Aluminium Oxide – hard metals, stainless steel, aerospace components

Glass Bead – cosmetic finishing for automotive and custom fabrication

Soda Bicarb – delicate substrates, façades, restoration

Industries: fabrication, transport, manufacturing

Best Equipment: GritBlast, RapidBlast, Graco/Wagner

Media: almandine garnet

Industries: heavy engineering, automotive, aerospace

Best Equipment: GritBlast, vapour blasting cabinets

Media: aluminium oxide, glass bead

Industries: rail, transport & logistics

Best Equipment: GritBlast, vacuum recovery systems, RapidBlast

Media: garnet, steel grit

Best Equipment: VAPR-Blast, RapidBlast

Media: crushed glass, garnet

Industries: agriculture, rail, heavy machinery

Best Equipment: RapidBlast, GritBlast, pressure pots

Media: garnet, steel grit

Victoria’s industrial ecosystem demands high productivity, reliability and compliance. Quantum Blast’s Victorian division supports these requirements with:

High-output GritBlast dry blasting systems

VAPR-Blast wet blasting units

Vapour blasting cabinets

Vacuum recovery systems

Graco and Wagner coating equipment

A full range of abrasive media, led by almandine garnet

All supplied directly through our Campbellfield depot for fast state-wide delivery. For tailored recommendations or supply across Victoria, contact Quantum Blast.