1. Introduction: Abrasive Blasting in Queensland’s Harsh Industrial Environments

Queensland is home to some of Australia’s most demanding industrial sectors: LNG plants in Gladstone, defence and marine yards in Townsville, mining supply chains in Rockhampton, shipyards and aviation hubs in Cairns, and major civil and commercial infrastructure throughout Brisbane.

Across these environments, abrasive blasting isn’t occasional — it’s essential. Corrosion, marine fouling, UV degradation, mineral buildup, humidity-driven oxidation, and heavy-duty wear all require constant surface cleaning, profiling, coating removal, and surface preparation.

That’s why Queensland operators rely on equipment that is tough enough to thrive in extreme tropics, efficient enough for high-output workloads, versatile enough to support multiple abrasive media, safe and compliant with environmental requirements, and supported by real local supply and service.

With five locations covering the state, Quantum Blast Australia delivers one of the country’s most advanced and complete blasting equipment ranges — from compact blast machines to vapour blasting cabinets, wet blasting units, vacuum recovery systems, abrasive media, safety gear, inspection tools and specialist blasting accessories.

2. Abrasive Blasting in Queensland: Challenges and Realities

Queensland’s climate and industries create unique challenges for surface preparation. High humidity and salt exposure accelerate corrosion, especially on steel structures, vehicles, mining equipment and marine vessels.

Large industrial footprints in mining, LNG, refinery and port environments require high-volume blasting on tight turnaround schedules. Environmental and dust control requirements are driving increased use of wet and vapour blasting, enclosed cabinets and dustless solutions to minimise airborne contaminants.

At the same time, industrial assets are diverse: from sugar mills and cattle processors to naval assets, pipelines, cranes, steel structures, marine hulls and aviation components — no single blasting method is enough.

This is why Quantum Blast offers a diversified product range, giving operators the right tool for each application, and helping them balance productivity, safety, cost and compliance.

3. The Quantum Blast Equipment Range

Quantum Blast Australia’s Product Range covers everything from compact spot blasters through to capital equipment like blast rooms, paint spray booths, vacuum recovery systems and abrasive recycling plants. Around that core sits a full ecosystem of media, hoses, nozzles, safety gear, inspection instruments and coating application equipment.

The key categories are outlined below.

3.1 Dry Blasting Machines and Mobile Solutions

Quantum Blast supplies a comprehensive series of portable and industrial blast machines suited to workshops, mobile contractors and large industrial operators.

Typical configurations include 100–200 litre blast machines for general-purpose workshop and site work; mobile and skid-mounted units for mine sites, fabrication yards, marine maintenance and shutdown crews; and spot blasting machines for touch-ups, weld prep and tight access areas.

Common applications include heavy rust removal, structural steel preparation, mobile mining equipment maintenance, trailer, chassis and component blasting, and large-scale industrial surface preparation before coating.

3.2 Wet Blasting Systems and Vapour Blasting Cabinets

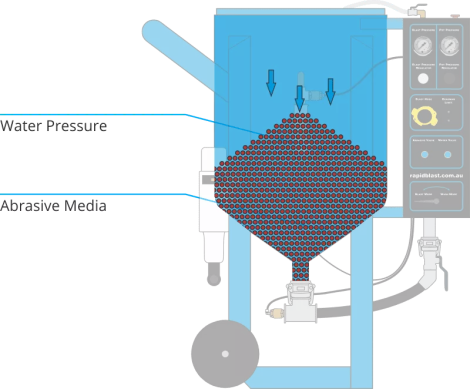

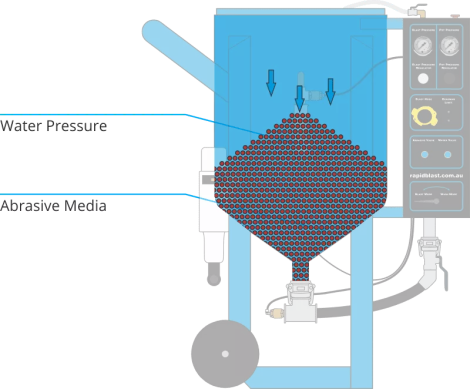

VAPR-Blast and other wet blasting systems are designed for dust suppression, safety and compliance. These systems mix water with abrasive media to create a cleaner, more controlled blasting stream.

Benefits include significantly reduced dust, better visibility at the workface, and a safer environment for operators and surrounding personnel. Wet blasting is ideal for marine and urban areas, sensitive environments and projects where airborne dust, noise and cleanup need to be tightly controlled.

Vapour blasting cabinets extend these benefits into a compact, enclosed format. They are widely used for precision parts, automotive restoration, aluminium and stainless components, aviation parts and marine components requiring a finer cosmetic finish.

3.3 Vacuum Recovery and Dust Control Solutions

Vacuum recovery systems allow operators to blast and recover spent media simultaneously. These systems help deliver low-dust blasting, media recycling and safe blasting around sensitive equipment and clean environments.

They are ideal for shutdowns, food and beverage plants, power generation sites, workshops and confined spaces where contamination control is critical.

3.4 Coating Application Systems

Blasting is only one side of the surface preparation story. Quantum Blast also supports the coating phase with equipment such as pneumatic and electric airless sprayers, electric diaphragm sprayers, conventional pressure pots, double diaphragm pumps and line marking machines.

These systems support the full coating workflow, from primers and industrial protective coatings through to linemarking and specialist finishes, helping operators go from bare steel to finished asset with a single integrated supply partner.

3.5 Inspection Instruments and Safety Equipment

Quality control, safety and compliance are non-negotiable in Queensland’s major industrial sectors.

That’s why Quantum Blast also supplies coating and wall thickness gauges, surface profile and environmental meters, hardness and adhesion testers, pinhole and holiday detectors, salt and dust contamination instruments, and concrete moisture and gloss meters. These tools enable proper QA/QC documentation and ensure that blasting work meets specification.

On the safety side, blast helmets, blast suits, breathing air filters, airline respirators, blast gloves and cabinet gloves, CO monitors, half-face and full-face masks, cartridge filters, climate control tubes, safety boots, safety gloves and safety goggles form a complete PPE package for blasting and coating teams.

4. Abrasive Blast Media Used Across Queensland

Abrasive media choice has a major impact on cutting speed, surface finish, dust levels, reusability and overall job cost. Quantum Blast supplies a wide range of media so Queensland operators can pick the right option for each project.

4.1 Garnet

Garnet is one of the most widely used industrial abrasive media in Queensland. It offers high cutting speed, relatively low dust, and can be recycled with appropriate recovery equipment. It is well suited for mining, marine, structural steel and heavy coatings removal applications and is used extensively across all five Quantum Blast depots.

4.2 Crushed Glass

Crushed glass has become a popular choice for many Queensland operators. It is typically lower in dust than some traditional slag products, environmentally friendly, and suitable for marine, industrial, automotive and civil applications. It delivers an excellent surface for coatings and is especially popular in coastal regions such as Brisbane, Gladstone, Townsville and Cairns where environmental and visual impact of dust is a concern.

4.3 Steel Shot and Steel Grit

Steel shot and steel grit are the workhorses of blast rooms and high-reuse environments. They are ideal for heavy industrial cleaning, aggressive coating removal and large structural steel work. With appropriate recovery and recycling systems, steel media can be reused many times, providing excellent cost-per-square-metre in fixed facilities.

4.4 Aluminium Oxide

Aluminium oxide is an extremely hard, sharp media used for precision blasting, hard metals, stainless steel and applications requiring a very consistent anchor profile. It is commonly used in cabinets and specialised blasting operations.

4.5 Glass Bead

Glass beads are used where a more cosmetic finish is required, such as peening, stainless steel polishing and cleaning of aviation and marine components. Glass bead blasting is popular in markets where surface aesthetics, not just cleanliness, matters.

4.6 Soda Bicarbonate and Soft Media Options

Soda bicarbonate is a softer blasting media suited to delicate substrates, automotive paint removal, restoration projects and heritage work. It can remove coatings without creating a heavy profile or damaging the underlying substrate, making it ideal for conservation and sensitive cleaning projects.