Hydra Blast Restorations

I have to emphasize, the Garnet that Quantum Blast has supplied me, is the best i have ever used, and i have used quite a number of different manufacturers.

Adelaide, Brisbane, Sydney, Townsville, Cairns

Premium sand blasting Garnet available with Chloride levels under 25ppm.

Hardness 7.5-8.0

20/40, 30/60 or 80 mesh

Available in 1T bulker bags or 40x 25kg bags (1T)

I have to emphasize, the Garnet that Quantum Blast has supplied me, is the best i have ever used, and i have used quite a number of different manufacturers.

Rock Garnet or Almandine rock garnet is found in underground deposits.

The raw garnet rocks are crushed into sharp angular, chunky fragments ideally suited for aggressive blasting.

Almandine Garnet grain’s natural physical and chemical properties offering low dust levels, angular shapes, high specific gravity and hardness make it most suitable for use in the blasting industry.

Alluvial garnet is typically found on riverbeds or natural hollows where it has been displaced by running water.

As it is exposed to the constant impact or tumbling from the waves, beach and river garnet tends to be of smaller mesh sizes and rounder in shape compared to the angular faces of rock garnet.

Grain shapes are important factor in blasting efficiency.

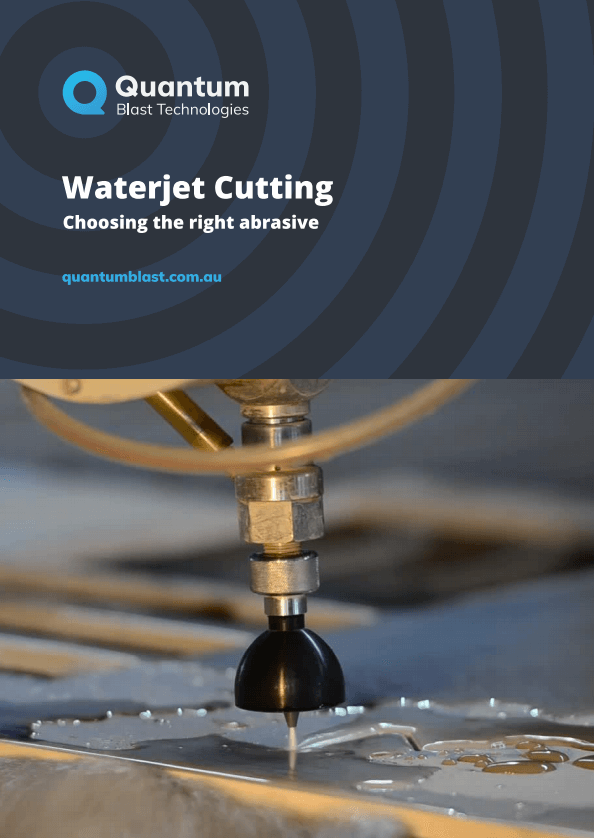

Our 80 mesh Abrasive Garnet is perfect for waterjet cutting.

Don’t take our word for it, read for yourself!

Abrasive media refers to granular materials used in sandblasting to clean, smooth, roughen, or shape a surface. It is propelled at high speed by compressed air or water to remove contaminants such as rust, paint, scale, or dirt, and to prepare the surface for further treatment like coating or painting.

Angular abrasive media (like crushed glass, garnet, and aluminium oxide) produce a more aggressive cutting action and result in a rougher surface profile. Spherical media (like steel shot or glass beads) are less aggressive and are better suited for peening or smoothing applications.

The Mohs hardness scale helps assess the cutting ability of media. Harder media like aluminium oxide (Mohs 9) or garnet (7.5–8.0) cut faster and deeper but may damage soft surfaces. Softer media like soda (2.5) are less aggressive and safer for delicate applications.

Yes, many abrasive types including garnet, crushed glass, and soda can be used in both dry and wet blasting. However, media like aluminium oxide or steel grit are typically used in dry systems due to contamination risks or moisture sensitivity.

Soda blasting is a non-destructive method of abrasive blasting that uses sodium bicarbonate (baking soda) as the blasting media. It is highly effective for applications that require gentle cleaning or where surface integrity must be preserved.

Key uses include:

– Fire restoration (removing soot and char)

Yes, soda blasting is safe and recommended for delicate substrates. Sodium bicarbonate is a soft, non-destructive media (Mohs hardness ~2.5), making it ideal for use on materials where traditional abrasives may cause damage.

Examples include:

Yes, soda bicarbonate can be used in wet blasting systems, provided the blasting pot and valves are compatible with the finer particle size and lower density of soda.

Considerations when using soda in wet systems:

While soda blasting has many advantages, there are several limitations:

Yes, many types of abrasive media can be reused depending on the material, operating environment, and application. Media used in enclosed blast cabinets or blast rooms is more likely to be recycled effectively. Wet blasting systems generally result in less media reuse due to moisture and slurry removal.

Typical reuse cycles:

Used abrasive media must be disposed of in accordance with environmental regulations, especially if it has stripped hazardous materials like lead-based paint. Contaminated media may be classified as industrial or hazardous waste. Non-toxic media such as soda bicarbonate may be easier to dispose of but always consult with local waste authorities.

Mixing abrasive media is possible, but should only be done for specific applications within a controlled process. Different media have different densities, hardness levels, and cutting abilities. Mixing can lead to inconsistent results and equipment wear.

Risks of mixing media include:

Not all abrasive media are suitable for all blasting equipment. Compatibility should be verified based on the following factors:

Quantum Blast’s RapidBlast™ dustless blasting systems are compatible with most major media types including garnet, crushed glass, aluminium oxide, and soda bicarbonate (with appropriate settings). The GritBlast dry blasting equipment is compatible with all abrasive media types popularly used.